Motor Manufacturing

Maxmore delivers high precision motor manufacturing supported by fully integrated in house production. From coil winding to complete stator assembly, we maintain full control over quality, timing and cost. By combining German quality expectations with the speed and flexibility of Chinese manufacturing, we create reliable and efficient motor solutions for demanding applications.

Winding Technologies

Maxmore operates three advanced winding technologies that allow perfect adaptation to different motor designs:

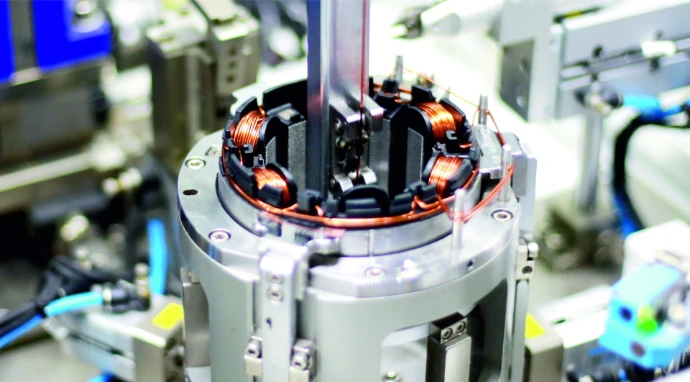

Needle Winding

Ideal for complex slot shapes with very accurate wire placement. Perfect for advanced designs and tailored motor solutions.

Flyer Winding

Efficient and stable for classic stator designs. Ensures uniform coil layers and is well suited for medium to high production volumes.

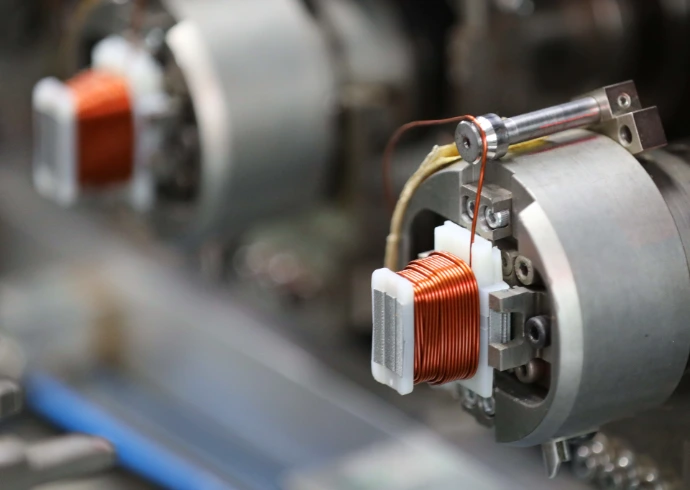

Linear Winding

Flexible method for special coil geometries and custom wire routing. Delivers high fill factor and great precision for compact high performance motors.

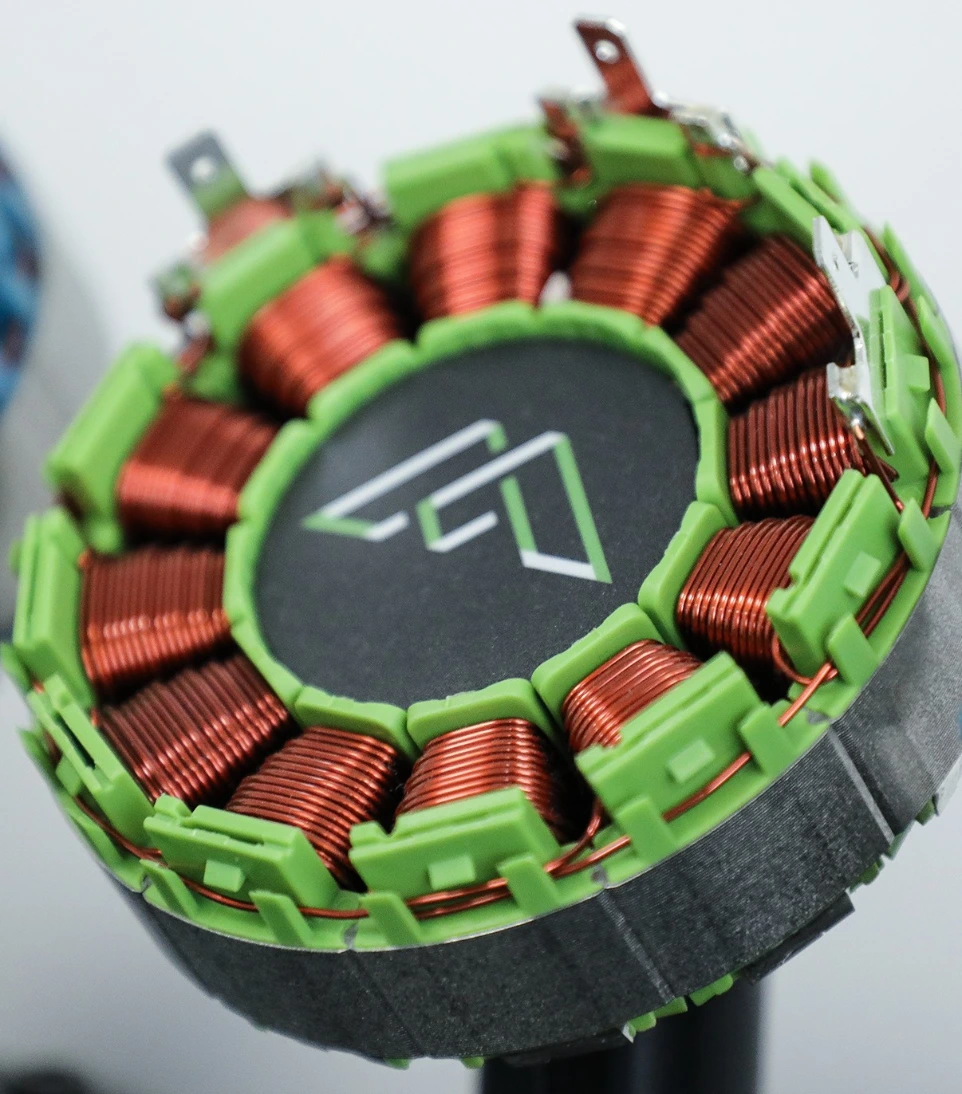

Stator & Rotor Capability

Stator Size Capability

Diameter = 30 mm -> 400 mm

Height = 10 mm -> 300 mm

This allows production of compact small drives as well as large high power stators.

Wire Capability

Diameter = 0.1 mm -> 5.0 millimeter

Types = Round wire and flat wire

Flat wire offers increased slot fill and excellent efficiency for high performance motors.

Connection Technologies

Soldering & IDC and crimping solutions

Laser & Resistance welding

Maxmore provides several reliable connection methods to ensure durable and clean electrical contact

Stator Overmolding

Maxmore provides complete startor overmolding for lamination stacks using tooling designed and built in-house. After the winding process, a second overmolding step is possible to add protection and structural stability.

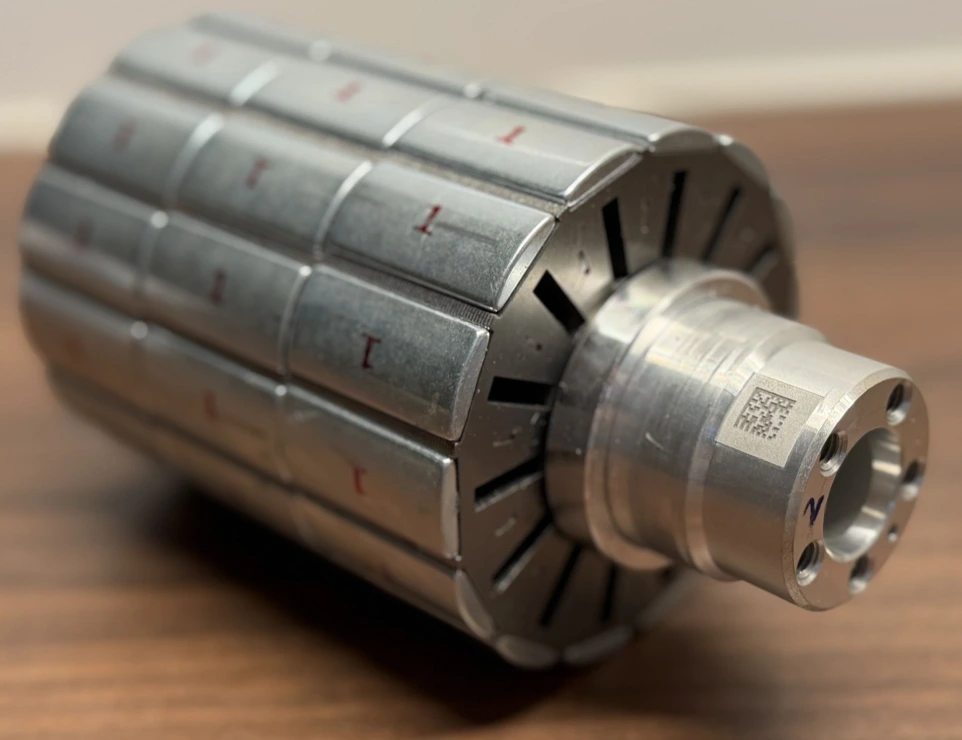

Magnets

We source and integrate every magnet type available on the Chinese market, giving full freedom in material selection and performance. HRE free magnet solutions are also fully supported.

Any magnet, any grade, always available at the source.

Rotor Size Capability

Full flexibility from small precision rotors to large scale assemblies.

Integrated Shafts

We produce rotors with integrated shafts in metal or engineering plastics, including fully overmolded designs for maximum stability and precision.

Integrated shaft solutions tailored for strength, precision and seamless

Rotor Balancing

Rotor balancing is performed entirely in-house with advanced equipment to ensure smooth operation, low vibration and optimal motor efficiency. Our process supports both low volume and mass production needs.

Integrated shaft solutions tailored for strength, precision and seamless